Products

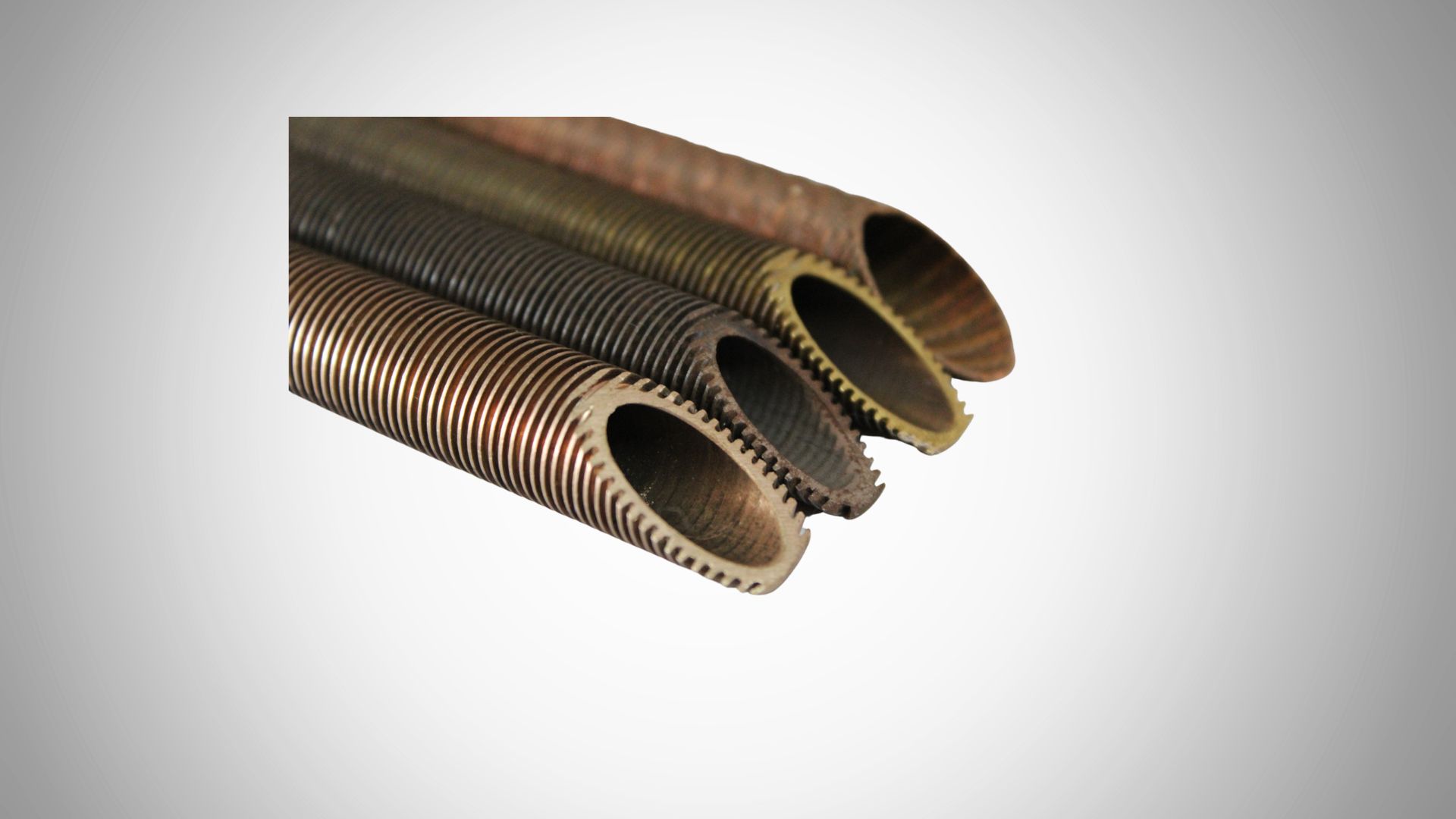

Integral Finned Tubes

Integral fin tubes were developed to increase the heat transfer performance of fluids while reducing the physical size and cost of the heat exchanger.

Read more

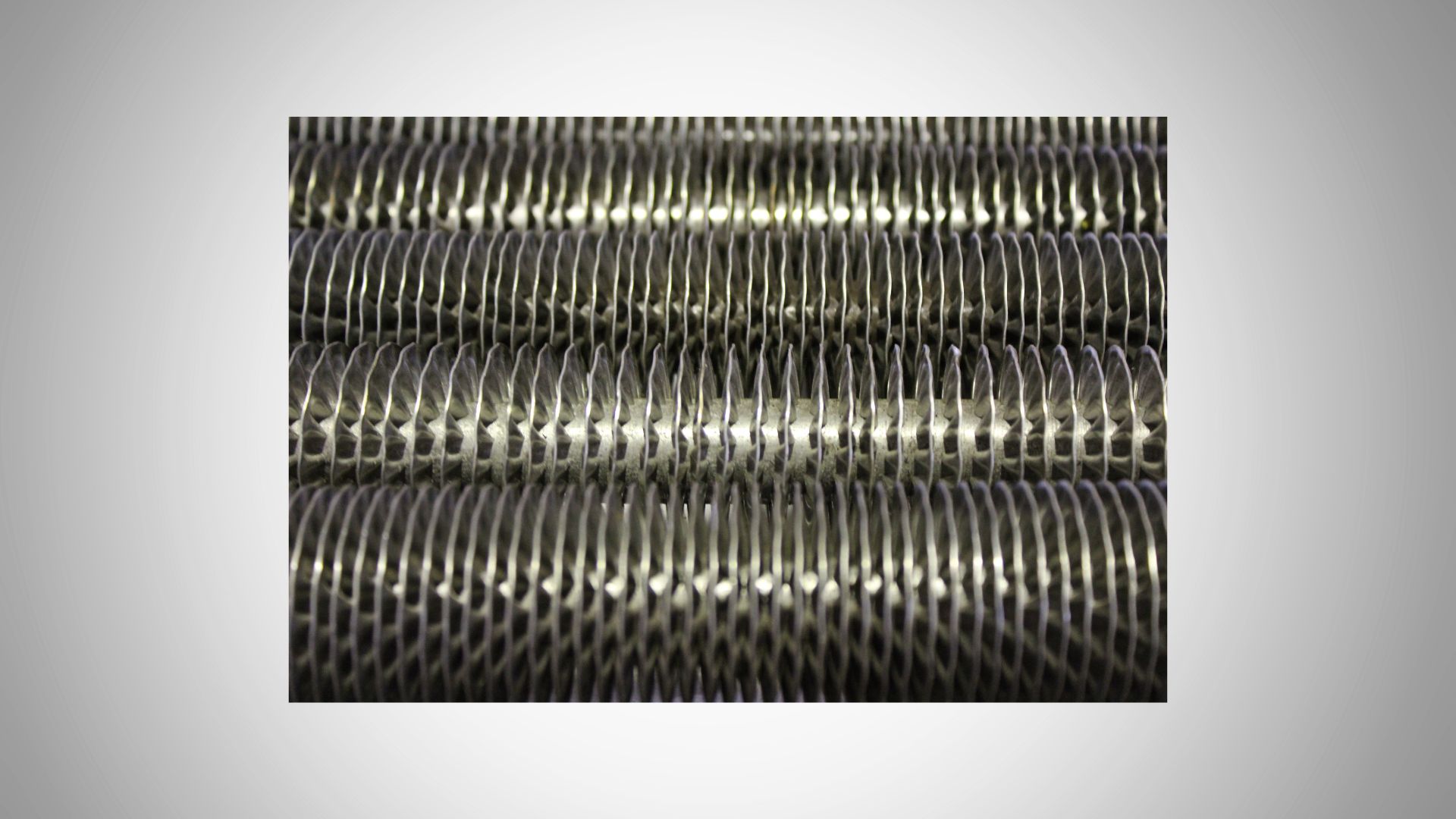

External Finned Tubes

Applied fin tubes are manufactured by wrapping the fin material around the base tube to give it the required characteristics for the process application.

Read more

Corrugated Tubes

CORRUGATED Tubes are formed by making a spiral groove along the surface of the tube through a specialised rolling process.

Read more

Cooling Coil

Cooling Coils are the best option as they are compact and at the same time provide the same Efficiency and Heat Transfer as the Straight Tubes.

Read more

Extruded Fin Tubes

Extruded finned tubes are highly sturdy and durable finned tubes, able to sustain higher pressures and temperature in the range of 350Deg.

Read more

U Bend Fin Tubes

We at NFTPL, offer U bending on finned tubes for more compact and efficient heat exchangers. These bends are checked for all bend parameters as per ASTM / TEMA and IBR standards. The bend radius is customized as per client requirement.

Read more